Post by Bettina Brammer - Head of Marketing, Meyer Burger - 03/04/23

Uncompromisingly sustainable

More solar power was generated in the EU last summer than ever before - a good sign. After all, how we can make our energy world emission-free is the question par excellence for the future. However, green electricity alone is not enough. The production of solar cells and modules must also become more sustainable.

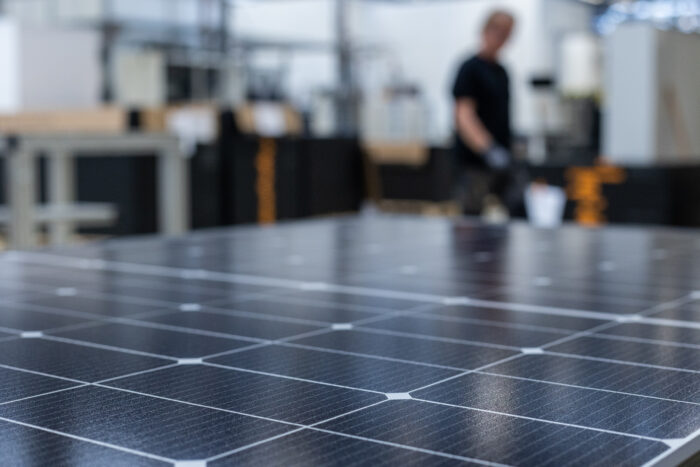

Energy generation from solar power and sustainability go hand in hand. Theoretically, solar power does not produce any greenhouse gases and is therefore one of the most environmentally friendly forms of energy. In practice, however, emissions still occur - especially in the production and transport of cells and modules. That is why the German-Swiss solar module manufacturer Meyer Burger pursues a sustainability approach that covers the entire value chain.

The vision: The green solar module

Two years ago, Meyer Burger decided to no longer just supply the technology for manufacturing solar cells and modules, but to manufacture innovative high-performance cells and modules itself - and to do so exclusively in Europe. "We took this step not for image reasons, but out of conviction. Because local production has the advantage that we can always keep an eye on our sustainability standards and implement our vision of the green solar module in the best possible way," says Gunter Erfurt, CEO of Meyer Burger.

The most resource- and environmentally-friendly solutions are therefore used in operations. This not only includes the fact that Meyer Burger supplies its production facilities in the heart of Europe with energy from 100 percent renewable sources. The company also prefers to work with regional suppliers - this helps to shorten transport routes and reduce emissions. Production itself has also been optimised. The solar cells and modules with Heterojunction SmartWire Connection Technology are manufactured using a low-temperature process. This conserves the material used and additionally reduces energy consumption.

Meyer Burger advantage: Significantly better environmental balance

An important key figure in connection with the sustainability of photovoltaic modules is the Life Cycle Assessment, i.e. the systematic analysis of the environmental impact of products, processes or services along their entire life cycle. Together with the renowned experts at the Fraunhofer Institute for Solar Energy Systems in Germany, Meyer Burger conducted such a Life Cycle Assessment (LCA) and looked at the entire product life cycle of its own solar modules: from raw material extraction to production and module recycling. The result of the LCA: Meyer Burger modules produce a total of 24 percent (for glass-backsheet modules) and 36 percent (for glass-glass modules) less CO2 than comparable PERC modules. The advantage comes in part because wafers Meyer Burger uses are made from polysilicon produced by Wacker. Wacker produces the majority in Germany, which saves 42 percent CO2 . In addition, the much shorter transport routes for European customers reduce emissions by 88 percent CO2. In addition, the LCA confirmed all Meyer Burger modules have a very low energy payback time (= time it takes a module to re-produce the energy required for its manufacture) of less than one year in a temperate continental climate.

No toxins and comprehensive recycling

Natural resources are the basis for life on this earth. Accordingly, they should be treated with care. At Meyer Burger, all production processes have therefore been adapted and optimised. As a result, the consumption of silver has been reduced by 65 percent. Thanks to a special combination of materials, Meyer Burger solar modules are free of toxic substances such as lead and fluoropolymers. In the long term, all modules are to be fully recyclable: "By reusing, sharing, repairing, refurbishing and recycling, we want to adopt the principles of the circular economy to avoid waste, pollution and carbon emissions. In the long term, we want to change our business model to the "Cradle2Cradle" concept and not only limit our company's negative impact on the environment, but go further and leave a positive footprint," explains Katja Tavernaro, Chief Sustainability Officer at Meyer Burger.

United Nations Sustainable Development Goals as a commitment to action

In 2015, the United Nations defined a total of 17 sustainable development goals for people and the environment that apply to all member states. Meyer Burger is also committed to participating in the implementation of these goals and making an active contribution to climate protection. The focus is on energy and environmental issues. For example, Meyer Burger is committed to significantly increasing the share of renewable energies in the global energy mix, to ensuring that new PV technologies make the availability of electricity globally feasible, and to ensuring that a large proportion of the raw materials used are fully recycled and further processed in a way that conserves resources.

About Meyer Burger

Meyer Burger is leading photovoltaics into a new era worldwide. Meyer Burger combines innovative cutting-edge technology with tradition and courage to create unique photovoltaic systems and production facilities. For almost 70 years, we have been the technological backbone of the industry and set standards - from diamond wire saws and industrial PERC solutions to precision measurement technology for solar modules. The vast majority of solar modules produced worldwide today are based on technologies developed by Meyer Burger. Now we are taking the next step and have reinvented our business model: As a manufacturer of high-performance photovoltaic cells and modules, we are using the heterojunction/SmartWire technology we developed to lead photovoltaics into a new era worldwide. In terms of energy yield and efficiency, we define new standards and combine them with first-class design. Our edge pushes us to innovate further every day. Innovations that go beyond our materials and craftsmanship and ensure that our product pays off. For everyone. For a solar future!

Meyer Burger modules available at CCL Components - click here to browse